Solar Panel Quality Guide

Table of Contents

How Reliable are Solar Panels?

The reliability and lifespan of solar panels are excellent, according to the recent study by the National Renewable Energy Laboratory (NREL), a federal laboratory dedicated to researching renewable energy efficiency technologies. If you're considering getting solar for your home or commercial property, it is essential to understand why solar panels fail and if you should be concerned with their quality.

Back in 2008 when solar was still being introduced to the general market, the technology for solar panels was quite poor in terms of efficiency and there were a lot of issues that resulted due to equipment failure. When you consider it's now 2019, and the manufacturing process is a lot more advanced and with the degree of testing quality, solar panel manufacturers' conduct you can be confident that the current failure rate is even lower. Ensuring that the cost of going solar is outweighed by its benefits in the long haul.

The most reliable solar panel manufacturers offer a power output warranty of at least 25 years. The odds of your solar system ever experiencing failures are extremely unlikely; even if it does, you will be covered by the warranty, and the panel will be replaced free of charge.

Why Do Solar Panels Fail?

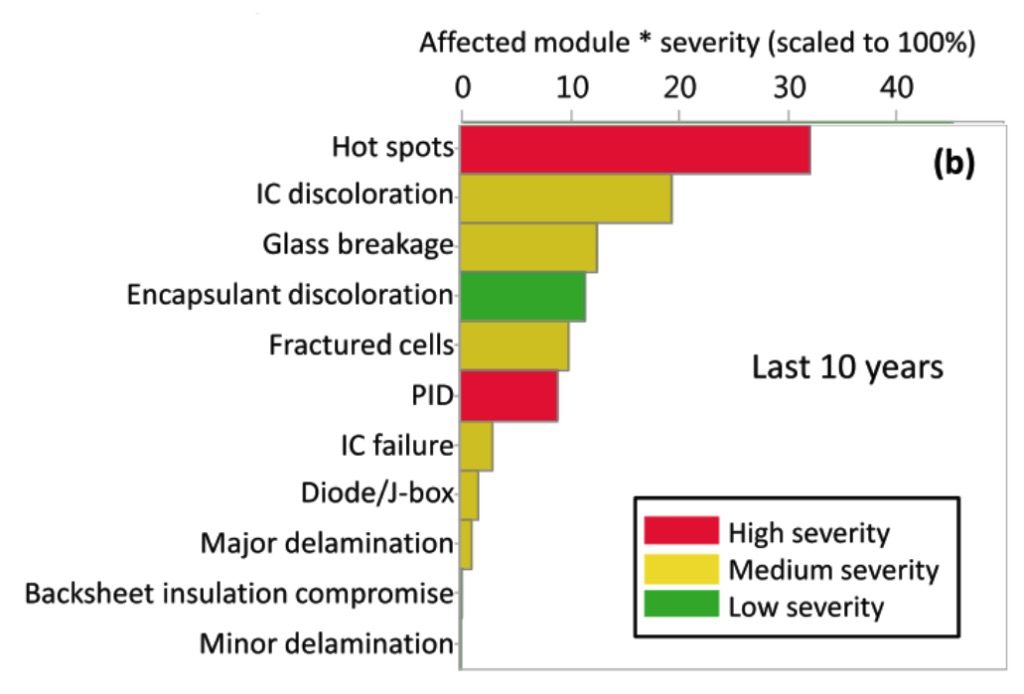

You should feel confident that if you do purchase a solar energy system, your panels should not fail and that you're backed by a great warranty that will address any issue that may arise. Different failure modes can impact your solar modules that range from Hot spots to minor delamination. Have confidence that if you go with a reputable solar panel manufacturer their solutions provide a quality solution that is backed by proper testing. A reputable solar panel manufacturer should not only have fewer errors but also stand by the quality of its solar panels through equipment and performance guarantees.

Solar Panel Failures Explained

Top 10 Modern Solar Panel Failures

- Hot Spots

- Interconnection discoloration

- Glass Breakage

- Fractured Cells

- IC Failures

- Diode / J-box

- Major Delamination

- Backsheet Insulation Compromise

- Minor Delamination

Hot Spots – Hot spots typically occur when panels are locally shadowed. This is the most common issue that impacts the efficiency of a solar panel system. The great news is, it is typically preventable when localized shading is removed.

Localized shading is typically addressed when you do your installation. Your solar energy system installer will help point out areas of shading that can impact your solar energy system.

IC Discoloration -This is a discoloration of the interconnection (IC). This is typically seen when the interconnection changes to more of a rusty hue. It is a sign that there could be corrosion in your panels. It isn’t a failure necessarily but could highlight the need to ensure proper monitoring of how much your solar system is generating.

(Photo Credit: Q.Cells Partner Program)

Gas Breakage – This is due to a few different applications. Typically panels are incredibly durable, and the glass is exceptionally resilient. However, enough blunt force can crack and break the glass that encases the solar panels.

(Photo Credit: Q.Cells Partner Program)

Fractured Cells – Are a normal phenomenon during a panels service life and can be caused by challenging weather, or by improper transportation or incorrect handling during installation.

PID - (Potential- induced performance Degradation) This is an issue that is caused by so-called "stray" electrical currents. This leads to a substantial loss in efficiency and could lead to a power loss of up to 30%. This is typically a cause of environmental issues with respects to high temperatures and high humidity.

IC Failures – Interconnection failures are typically infrequent. The reason for the failure is due to the soldering process.

Diode / J-Box – The diodes’ main task is to protect the solar panel cells from overheating when partial shading occurs. This failure is very rare and typically occurs during the manufacturing process where the diode isn’t properly connected or was damaged.

Major Delamination – Process is where the components are coming apart. This is typically when the bond that holds the plastics and the glass separate. This can lead to issues since it allows air and moisture to creep inside the panels which can lead to corrosion, disfiguration, and potential failure.

Backsheet Insulation Compromise – Backsheet is failing. This is a serious problem because the back sheet acts as an insulation layer and is typically very reliable.

Minor Delamination – The process is where the components are starting to show signs of coming apart. It is a lesser form of major delamination and typically occurs where inferior plastics or bonding is used.

2 Types of Problems that Impact Solar Panels

Mechanical Problems

Cheap Solar Panels can Come with Mechanical Problems such as:

- Bent Frames

- Broken Cells

Mechanical Problems Typically Arise:

- Transporation

- Installation

- Operation

Manufacturing Problems

Cheap Solar Panels can Come with Manufacturing Problems Such As:

- Cracked Solar Panels

- Warped Frames

Manufacturing Problems Typically Arise:

- Cheap Plastic

- Poor Soldering

Historical experience shows failure modes are evolving where the overall number of problems that occur in panels is decreasing but mechanical problems are becoming more common. This highlights the importance of using a quality installer to ensure that the transportation of the solar panels and installation of the solar energy system is properly conducted to ensure that your solar panels work as efficiently as expected.

Solar Panel Testing

Both manufacturing technology and the application environment contribute to the failure of the solar modules.

In order for panel manufacturers to improve solar panels, they conduct two types of tests.

Functionality Tests

Functionality tests measure whether or not the solar panel will meet the efficiency specifications that they propose.

Reliability Tests

Refer to tests designed for gauging if the modules can survive in various environments and conditions.

Functionality Tests

Checks for visual defects on the PV panels and to ensure that the glass does not have any scratches.

Light Test - The panel will be measured with an artificial sun spectrum to determine power, current, and voltage values.

Electroluminescence (EL) Testing - The solar panel will be tested for defects with regards to the electrical flow. This type of testing injects electricity into the panel to generate infrared light (heat). This is the reverse process of how a solar panel operates typically.

During this testing, if the cells are darker in color, that means that the currents passing through is not as efficient.

If the current doesn't pass through, that means it is darker, so we will see things like cracks based on the EL test results.

Solar Panel Fact: In a solar panel, all panels are not the same. There is a small power difference across every solar panel section.

Reliability Tests

Damp Heat (DH) - Induces stress resulting from high humidity at very high temperatures.

Testing Conditions: Constant Temperature of 185* and humidity of 85%

Testing for Solar Panel Issues: Corrosion, discoloration, and connector issues.

Thermal Cycling (TC) - Induces stress with high and low temperatures.

Testing Conditions: Solar Panels undergo multiple cycles in 185*F to -40*F environments.

Testing for Solar Panel Issues: Cell Cracks, Mechanical instability.

Humidity Freeze (HF) - A combination of the damp heat and thermal cycling.

Testing Conditions: 85% Relative humidity at 185*F while cycling to -40*F.

Testing for Solar Panel Issues: Cell Cracks, Mechanical Instability, and Delamination.

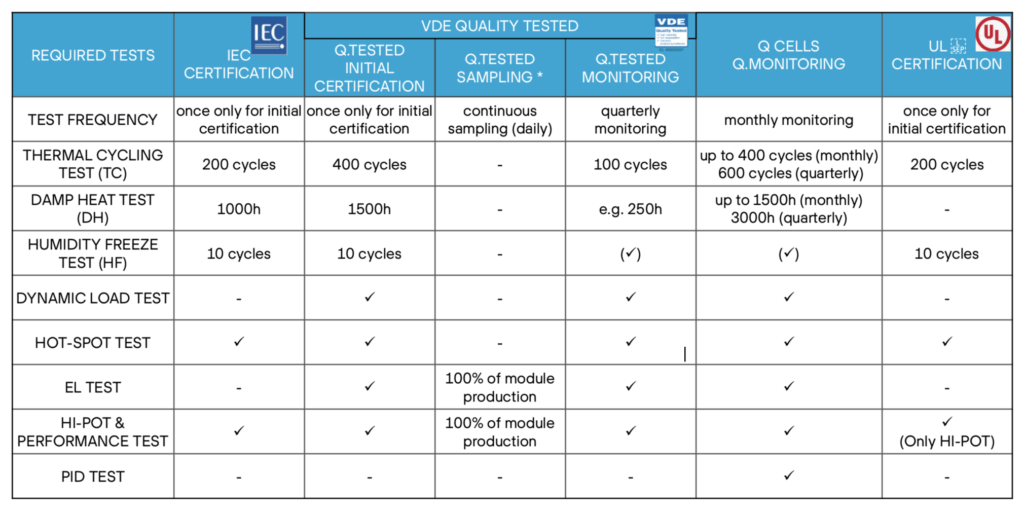

Solar Panel Certifications and Qualifications

Product Certifications and Qualifications are factors that you should ensure your solar panels also come with.

Approvals from market standards like IEC, UL, MCS, KS, and/or CQC are essential to ensuring that your module meets design safety and will perform to expectations.

We typically work with solar panel manufacturers that go beyond the standard testing. For example, Q CELLS not only meets external certification agencies like IEC and UL, but they also have their own internal testing certification requirements to ensure that their panels truly match the efficiency specifications they outline in their datasheets.

Your Solar Panel Repair Experts

Are your solar panels not running as efficiently as they should be? If you’re local to San Diego, Riverside, Los Angeles, San Bernardino, or Orange County, we can make sure that you get a quality solar panel install at a cost that you can afford. Click here for a quote. Contact us for high quality, low-cost solar panel installation.

Call Forme Solar Inc, your Riverside, San Diego, Los Angeles, San Bernardino, and Orange County solar panel repair and service specialists, now at (714) 694-2262, to make an appointment with our friendly and knowledgeable staff.